Tel: +44 (0)151 922 0610

Slide title

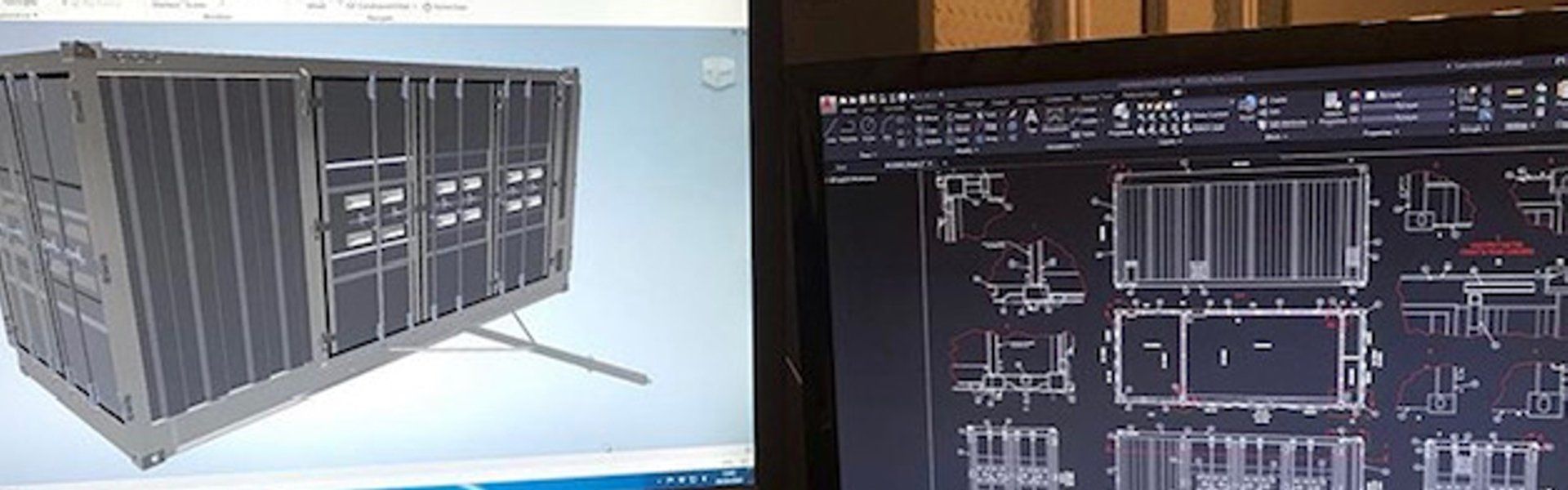

Flexible, modular solutions for all sectors

Button

Slide title

Expert design team driven by you

Button

Slide title

Precision engineered to your precise specifications

Button

Slide title

In-house painting for total quality control

Button

Slide title

Unrivalled reputation that keeps customers coming back

Button

Bespoke containers designed and built

Flexible, portable and affordable, modular container-based units are the answer to a wide range of service, storage and accommodation issues across all industry sectors. From offshore oil and gas, to on-site construction, from military applications to modular buildings, Bootle Containers can design bespoke, turnkey solutions to meet your exact requirements, manufactured and finished to the very highest standards.

At Bootle Containers we focus on quality, not quantity, offering design, build quality and finish that are a class apart. Every job receives the same attention, however large or small, because we believe that every customer deserves the very best. If that sounds like the kind of company you’d like to work with, get in touch with our team today on 0151 922 0610 or email info@bootlecontainers.co.uk.

DNV 2.7-1

LLOYDS CSC APPROVAL

ISO 9001

Working with you to find your perfect solution

At Bootle Containers, we are led by you. We fit our solutions to your challenges, not the other way around. There are no off-the-shelf answers, because we create each project individually, designing your unit to order to make sure it meets and exceeds your every expectation. We will use our unrivalled experience and expertise to collaborate with you, working together to deliver exactly what you need. No unit goes into production until you are completely satisfied with the design, and no unit comes out of our factory until we are completely satisfied with the quality.

- State of the art design offers you innovation and inspiration

- In-house manufacturing maintains standards throughout

- On-site paint shop saves you time and money, and guarantees quality

- Independent certification gives you complete peace of mind

- Constant communication keeps you involved at every stage

© Copyright 2019 Bootle Containers. All Rights Reserved.